WE WORK WITH THE BEST EARTH HAS TO OFFER

With these exceptionally strong resources, we established Marmonil Quarrying in 2009 to run and control the earlier phases of our vertical integration in stone extraction. This investment assures our capacity to

deliver premium quality stones in large volumes with color consistency. Our teams are always on the search for exploring new materials for our clients. We pride ourselves in being the country’s biggest and greenest producer of raw stone, using only sophisticated technology. We consult with expert geologists and conduct quarry planning to ensure that our extraction is done in a manner that is both cost-efficient and environmentally friendly.

INTRODUCING THE GALALA QUARRY

“EGYPT’S LARGEST QUARRY”

beige hues, it truly reflects the nature that surrounds it. Galala’s marble stock includes more than 1,000

cubic meters and each stone extracted from this quarry is versatile and can adapt to any design, making

it truly unique in all its applications. The quality of Galala’s stone is unparalleled and, as it was once

submerged underwater, remnants of a time past in the form of shells and fossils are sometimes found…

breathing life into each and every piece we extract.

INTRODUCING THE ASWAN GRANITE QUARRY

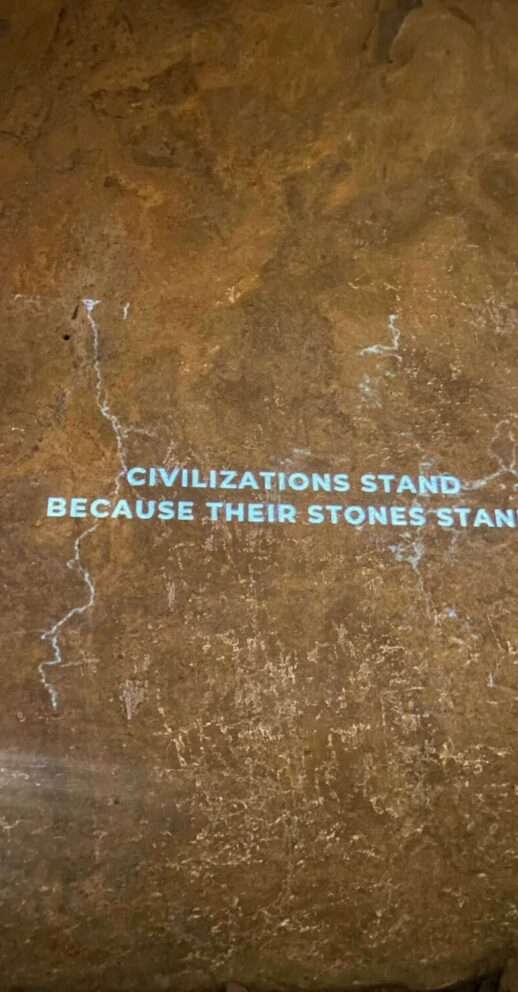

Marmonil houses exclusive material in granite that cannot be found elsewhere, thanks to our Aswan Quarry. Our Nero Aswan quarry in particular is the oldest in the world. Staying true to our ancestral roots, our Aswan granite quarries are those that were used by the pharaohs, paying testament to natural beauty that stands the test of time.

These ancient quarries are known for their red, grey and black granite variations with many of them becoming archeological sites. The world’s most stunning historical sites and monuments such as numerous ancient egyptian temples and Cleopatra’s needle are all made of exquisite black granite sourced from The Aswan Granite Quarry.

INTRODUCING OUR SINAI PEARL QUARRY

Our machines are equipped to apply all kinds of resins including Epoxy, Polyester and UV. Following resin applications, our edge is the Anti- Salt treatment we can provide on materials to prevent salt emissions in the last production stage before packing.